3 sets roll forming machine to Nigeris as following:(includeing double layer making machine、step tile making machine、metrocopo tile making machine)

Double layer roll making machine components:

(1) Manual decoiler 1 set(Capacity : 5 tons)

(2) Roll-Forming M/C 1 set (double layer forming)

(3) Hydraulic Cutting 1 set

(4) Hydraulic station 1 set

(5) PLC Control System 1 set

(6) Run Out Table 1set (two pieces, total length is 3 meters)

(7) Tool Box 1set

Step tile roll making machine components:

(1) Manual decoiler 1 pc (capacity:5 tons)

(2) Guiding Equipment 1 set

(3) Covering film device 1 set

(4) Roll Forming Equipment 1 set

(5) Pressing equipment 1 set

(6) Post-cutting Equipment 1 set

(7) Hydraulic Station 1 pc

(8) PLC Control Panel 1 pc

(9) Supporter Table 1 set (two pieces, 1.5m/piece)

(10) Tool Box 1 pc

Metrocopo tile roll making machine components:

(1)Manual decoiler 1pc (capacity:5 tons)

(2)Guiding Equipment 1set

(3)Covering film device 1 set

(4)Roll Forming Equipment 1set

(5)Pressing equipment 1 set

(6)Post-cutting Equipment 1set

(7)Hydraulic Station 1pc

(8)PLC Control Panel 1pc

(9)Supporter Table 1set (two pieces, 1.5m/piece)

(10)Tool Box 1pc

Zhongyuan is one famous brand in metal cold roll forming lines industry. In Nigeria, our customers praise Zhongyuan brand roof roll forming machines to be same quality level of BMW brand car in car industry.

Metal Double Layer Roll Forming Machine Main Technical Parameters:

quantity of rollers:upper 20 stations,down 30 stations

machine size:13.8L*1.75W*1.65H

main motor power:7.5KW hydraulic power:2.2KW

weight:16515kg

Metal Step Tile Roll Forming Machine Main Technical Parameters:

1) Working Speed: About 6m/min. (including the cutting& pressing time)

2) Main Motor Power: 5.5KW (Depend on final design)

3) Hydraulic Station Power: 5.5KW (Depend on final design)

4) Control System: Mitsubishi PLC and transducer (Japan)

5) Encoder: Nemicon (Japan)

6) Rollers’material: High grade No.45 forged steel, with digital-controlled procession,plated wit chrome on surface.

7) Shaft diameter: 72mm, tooled by grinding machine for two times to ensure the precision of final product.

8) Type of Cutting: Length-set cutting and post forming style

9) Electric Condition: 380V/3Phase/50HZ(or depend on customer)

10) Total Weight: About 9500 Kg

Metal Metrocopo Tile Roll Forming Machine Main Technical Parameters:

1) Working Speed: About 6m/min. (including the cutting& pressing time)

2) Main Motor Power: 7.5KW (Depend on final design)

3) Hydraulic Station Power: 5.5KW (Depend on final design)

4) Control System: Mitsubishi PLC and transducer (Japan)

5) Encoder: Nemicon (Japan)

6) Rollers' material High grade No.45 forged steel, with digital-controlled procession,plated wit chrome on surface.

7) Shaft diameter 72mm, tooled by grinding machine for two times to ensure the precision of final product.

8) Type of Cutting: Length-set cutting and post forming style

9) Electric Condition: 380V/3Phase/50HZ(or depend on customer)

10) Total Weight: About 9700 Kg

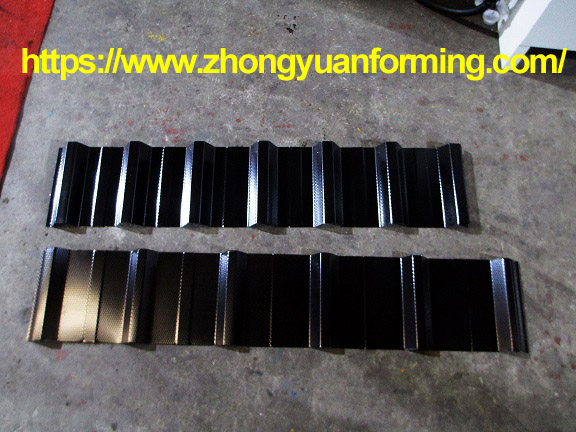

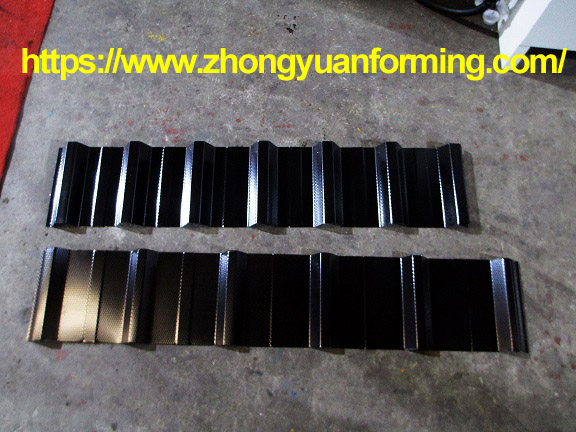

Steel roof produced from Zhongyuan Double Layer Roll Forming Machine:

Steel step roof produced from Zhongyuan Step Tile Roll Forming Machine:

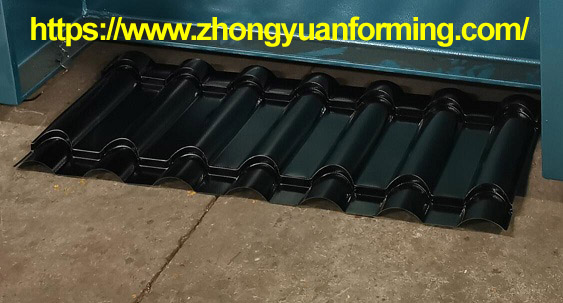

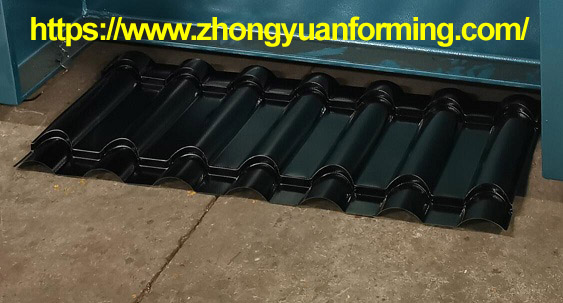

Steel metrocopo roof produced from Zhongyuan Metrocopo Tile Roll Forming Machine:

Packing pictures:

Contact Us:

Email: zhongyuanforming@hotmail.com

Mob. / Wechat / Whatsapp: +86 13867521382