The CZ Purlin Roll Forming Machine is a machine that produces purlins. Purlins are a bar or horizontal beams used in supporting structures in a building. The most known purlin machines in the market are C purlin roll forming machine, Z purlin roll forming machine and C/Z interchanging purlin machines. The purlin roll forming exercise is a metal forming exercise that deforms metal under high constraints via a sequence of unique-shaped rolls.

In steel construction, the purlin term means roof framing member spanning parallel to an eave of the building to hold the roof sheeting or decking. Since the wall or rafters hold C purlin, the pre-punched purlin is convenient to install and ideal for both uninsulated and insulated walls and roofs. The height and thickness of a purlin chosen rely on a span load and length.

Structures of Purlin Roll Machine

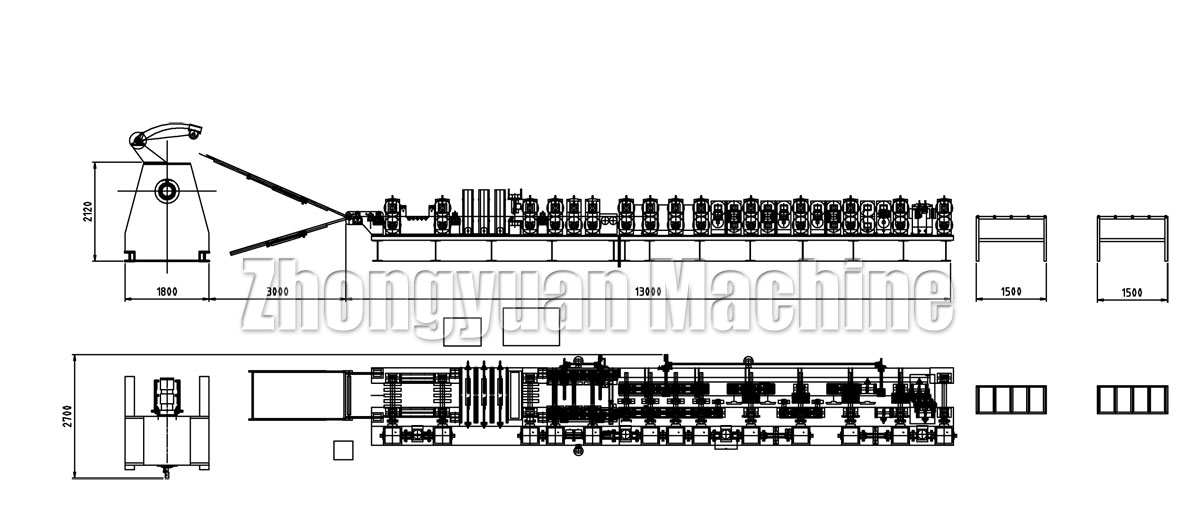

The main structures of the purlin roll machine work in a non-stop sequence. When the material is inserted into the machine, the machine continuously finds its way via all the stages of the operation. The end of the process produces a final and complete product. The purlin roll machine is designed with forming line, safety protection device, electronic control system, uncoiler, electrical control part, and cutting part.

The primary structure of the purlin roll machine includes:

Roll Forming Line

The roller comprises outstanding Cr12 molds to make eight sets of rollers. With an accuracy of 6 to 7, the precision CNC machine gadget also processes HRC steels amounting to 56 to 6o. With a result of 0.8 roughness, no scratches on top of the produced workpieces.

The forming line takes an integral permanent arch, a hole distance error that embraces less than o.1mm, and a side plate that embraces a 25mm steel plate. The part supporting the production line embraces a high-quality bearing, whereas the bearing embraces roller feed, which can adjust by rotating itself suitable and left, up and down.

The conveying part of the production line, known as the transition system, transmits its power to the gearbox from the motor to the driver wheel via the sprocket. The lower and upper rollers rotate synchronously due to the driving wheel transmitting the steel coil to the forming line front end.

Cutting Part

The cutting part comprises a shearing machine and a fixed-length tool. The fixed-length device controls the length via encoding. The produced C or Z purlin is cut, and the stamping is completed when the purlin reaches a specific length.

Uncoiler

Uncoiler is a unique tool used to level line steel plates. It can perform shearing production, levelling, and uncoiling and can also be configured to perform other sheet product production lines. The uncoiler is ideal for industries like vehicles, household

appliances, machinery, metal products, decoration, and steel structure.

The uncoiler part of the purlin forming machine is the gadget responsible for providing sheet materials and storing unwinding materials. It also firmly

delivers the steel coils to the forming production line chamber.

Safety Protection

A protective cover is installed on the primary transmission tool, with many warning signs set up in different places regarding individual safety while in the production line. There are essential safety grounding for electrical equipment, promoting the protection and enhancing individual safety.

Electronic Control System

The purlin production line entirely has a top-notch electronic control system. The electrical control components of the purlin roll machine meet international specifications, and you can also specify your desired parts. The component

requirements include a transparent line number, clear markings, and reasonable parts.

Feeder and Leveling

The roller feeder and leveling structure is the component where the bending process occurs. The deformation of the out of the flat part, plate, or sheet is performed by a series of interchanging bends. The interchanging bends are made by getting the sheet, part, or plate between sets of leveling purlin rollers.

Types of Purlin Roll Forming Machine

1.C Purlin Roll Forming Machine

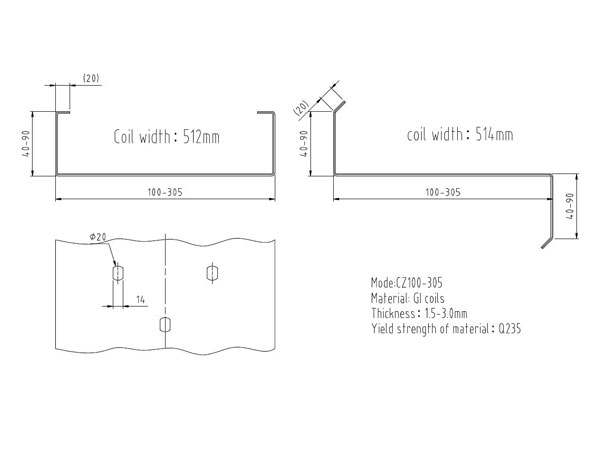

The C-shaped steel purlin roll forming machine is made of compelling cold force steel plates. Its symptoms of uniform wall thickness. The C-shaped steel made by cold bending adheres to the pressure symptoms of the roof purlin and can offer full play to the automatic performance of steel. The new c shape purlin has replaced the traditional purlin like channel steel, steel pipe, and angle steel.

2.Z Purlin Roll Forming Machine

The Z-shaped steel purlin machine can make different specifications of finished products of the Z shape purlin roll forming machine. It is a single-coil forming unit with a passive loading rack, a punching device, a cutting device after forming, a leveling

device, a computer control system, and a hydraulic station.

The Z shape steel machine can make cold-formed steel and various profiles of different materials, with complex cross-sectional shapes and consistent wall thickness that is hard to make by general hot rolling formulas.

It can be the significant bearing component of medium and prominent civil and industrial buildings, like the wall support of a warehouse, hangars, factory buildings, halls, and roof bearing loads.

3.C&Z Purlin Roll Forming Machine

The C&z purlin roll forming machine can make different C and z purlins specifications via manual improvements. You, therefore, don't need to change the roll if you want to produce a purlin of other specifications.

The production process will automatically adopt the control formula, which will cut, shape, and punch automatically according to the parameters input like a longitudinal hole distance, purlin length, and purlin quality.

CZ Purlin Machine Production Process

The production process of the CZ purlin machine is in the following sequence: Uncoiler to feeding, from feeding to leveling chamber, then to hydraulic

punching, after which it is moved to the hydraulic cutting. After the cutting process, the steel is moved to the roll forming section and the purlin output for the final product.

Where to buy the best CZ purlin roll forming machine?

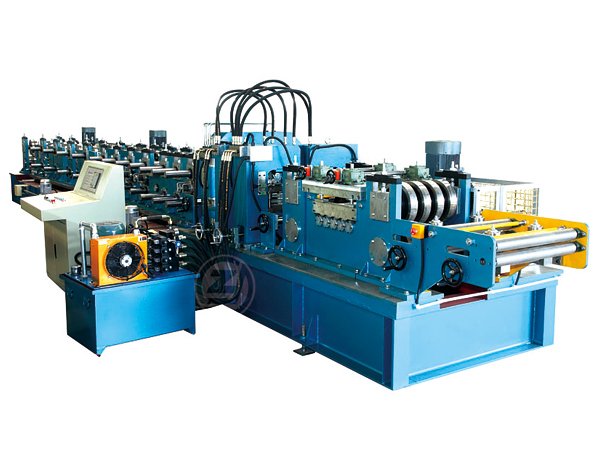

As a leading C/Z purlin roll forming machine manufacturer and supplier, Zhongyuan

offers the best purlin roll machines like C purlin roll machine, Z purlin roll machine, and C&Z purlin roll machine.

Zhongyuan machine's parts are made by experienced personnel with high precision, using the best quality rolling tools, so you never have to worry about the quality of the machine. All machines are quality controlled in accordance with ISO 9001 and CE requirements.