20+ Years Experienced Manufacturer for Roll Forming Machine

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

- HOME

- ABOUT US

- ROLL FORMING MACHINE

- Step Tile Roll Forming Machine

- Metal Sheet Roll Forming Machine

- Double Layer Roll Forming Machine

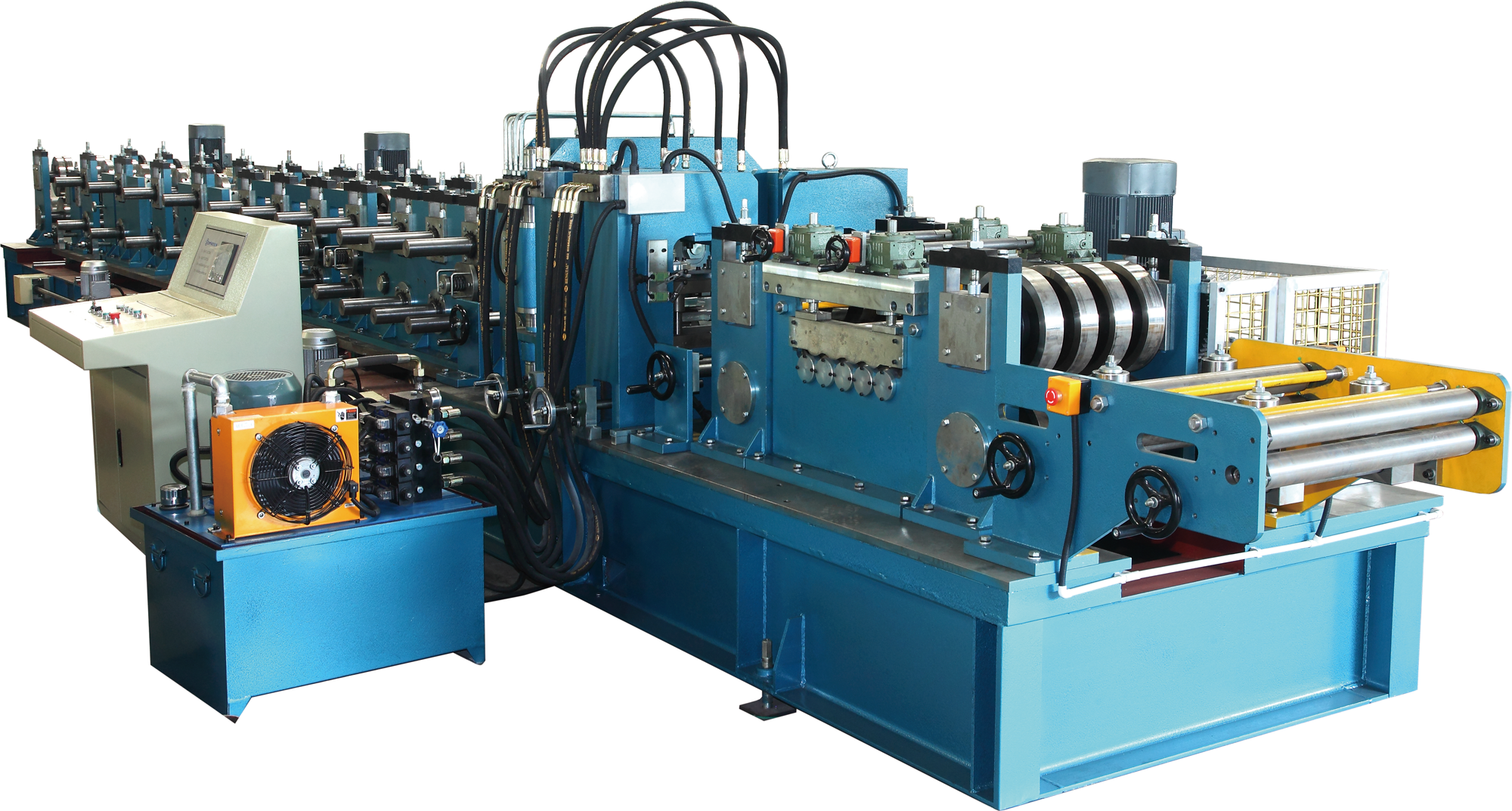

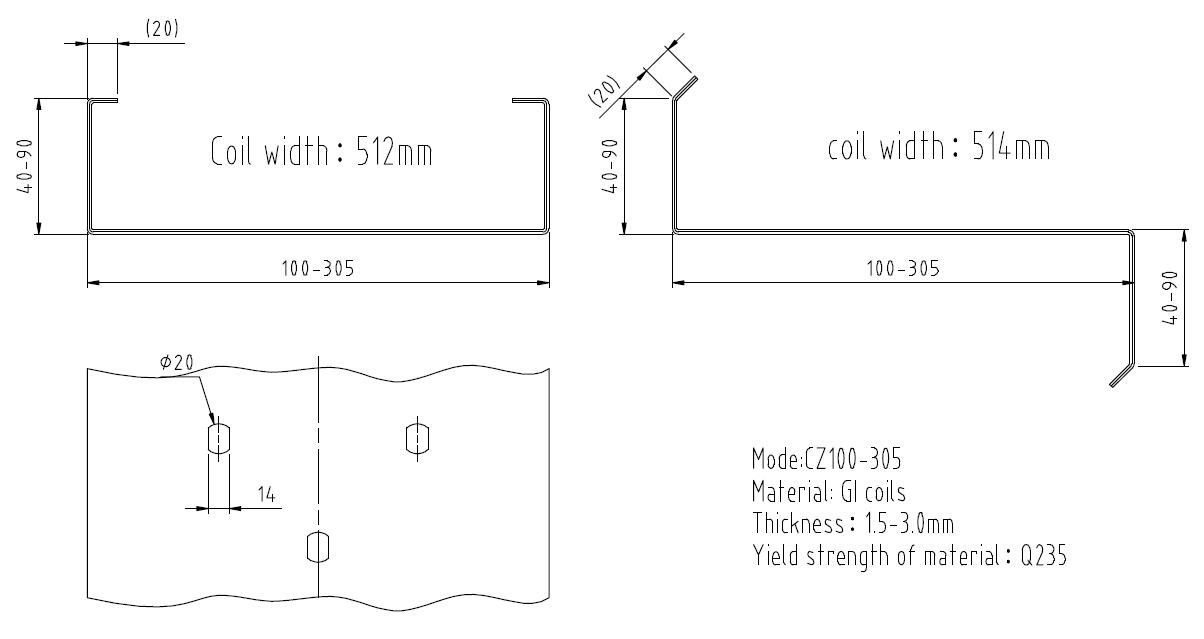

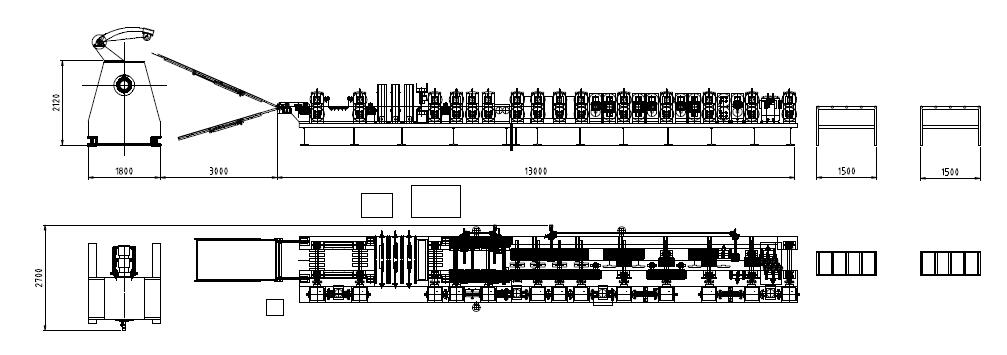

- Purlin Roll Forming Machine

- Metal Deck Roll Forming Machine

- Sandwich Panel Roll Forming Machine

- Guardrail Roll Forming Machine

- Gutter Roll Forming Machine

- Standing Seam Machine

- Sigma Forming Machine

- Cable Tray Roll Forming Machine

- Stud and Track Forming Machine

- Shutter Door Forming Machine

- Supplementary Machine

- APPLICATION

- SHIPMENTS

- NEWS

- CONTACT US