High Efficiency

High Precision

Easy Operation

About Our Company

Our R&D department has senior engineers with over 20 years of experience in the metal forming industry, so we are able to help our customers with professional designs and solutions.

We are the "in-house source for it all" - from the raw material to the final high precision forming machine. We can better control machine quality and machine delivery time.

The best solution for metal roll forming machines

So far, Zhongyuan metal roll forming machines have been sold to more than 30 countries and have received excellent feedback from customers there.

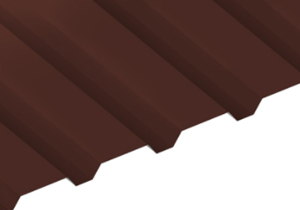

Roof Roll Forming Machine Gallery

Why Choose Us

Competitive Price

Timely delivery

Technical Support

Quality Control

Quality Guarantee

Expert Solutions

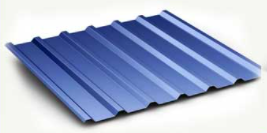

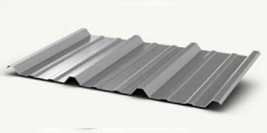

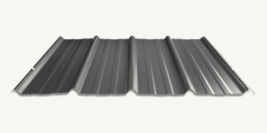

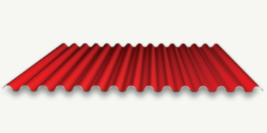

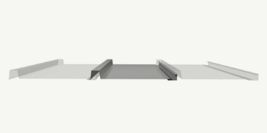

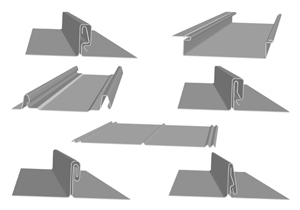

Metal Roof Panels Made by Zhongyuan Roll Forming Machine

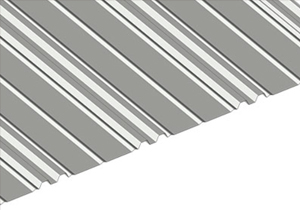

• TUFF-RIB panel profile

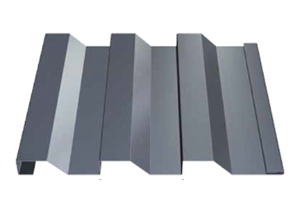

standing seam metal roof profile panels

belvedere plenum wall panels

grand V panels/grand C panels

span wall panel profile panels

We can provide custom roll forming machines that make the roofing panels you want.

Advantages

Long Life Machine

deformation. Cutting material is Cr12 mould steel with quenched treatment, all these processing steps ensure machine long life time.

High Precision

Automatic & Easy Operate

Global Customers Visit

FAQs

-

Q Are you a factory or a trading company?

AWe are a one-stop factory. Our company was founded in 2003 and has 19 years of production experience.

-

Q Where is your company?

AOur company is in Hangzhou, Zhejiang Province, which is only a 15-minute drive from Xiaoshan International Airport.

-

Q How long does it take to deliver the machine?

AHave the machine ready within 60 days after receiving the 30% deposit and confirming the details of the contract between the buyer and seller.

-

Q What is the warranty period of your machine?

AAll machines are covered by a 12-month warranty. Replacement of spare parts is free of charge during the warranty period. After the warranty period, we offer a lifetime maintenance service for the machines and provide spare parts at cost.

-

Q Do you accept OEM customization?

AThe roll forming industry is a non-standard industry and all machines are manufactured new to meet different customer requirements. There are no stock machines or used machines available for sale.

-

Q What is the minimum order quantity of your machines?

AYou can place an order for a single machine or order bulk quantities of roof & wall roll forming machines.

-

Q How do you ensure the quality of your machines?

AAll the steel used by Zhongyuan Machinery is from famous steel companies in China, such as Baoshan Steel and Shougang Steel. Each batch of steel has its own unique inspection certificate to ensure the quality of the raw material.

"All In House" allows Zhongyuan to better control the quality of the machines, maintain the same level of quality for all machines and ensure on-time delivery.

-

Q What kind of packing do you use for your machines?

A1. One *40GP container for a set of machines with mechanical decoiler.

2. Overall wiped with anti-rust oil and PLC controller covered with foam film.

3. Spare parts and some small parts are packed in the plastic toolbox.

4. All parts are fixed to the container with steel wire. Suitable for long-time ocean shipping.

-

Q How does your company provide after-sales service?

AThe equipment we supply will be delivered with a detailed installation and operation manual. We can provide free plant layout design. We will send our professional technicians to the customer's company to guide the installation of the machine and train the operators. All Machines will be delivered with one free cost spare parts box.

-

Q Does your company provide training?

AYes, we have a team of experienced instructors who can provide practical and adaptable training at your job site, during maintenance, or at our premises.