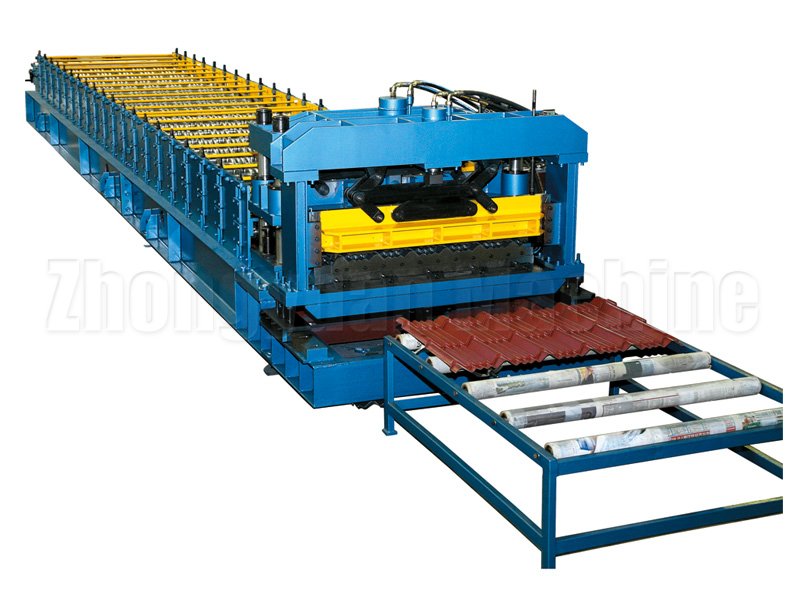

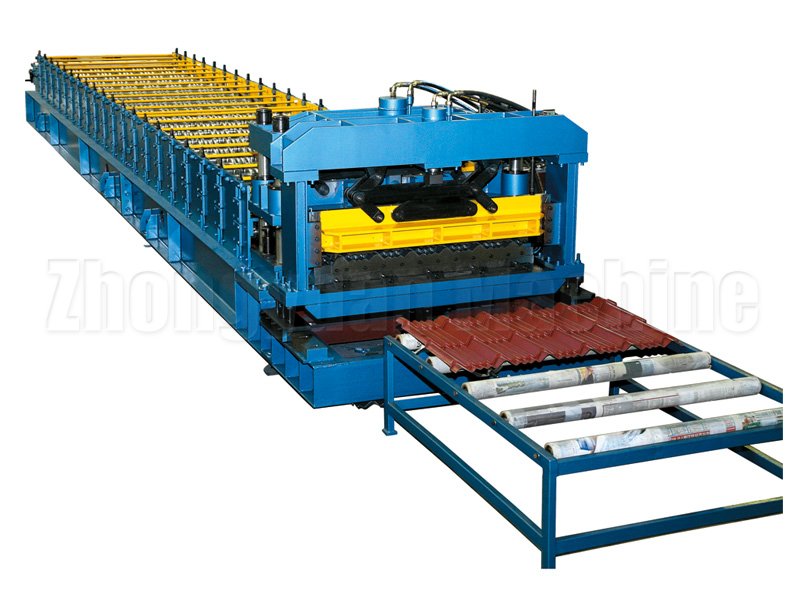

Various roof roll forming machines in different manufacturers have different maintenance to keep them serving you excellently and increasing their durability.

Unfortunately, not all consumers follow the strictly recommended maintenance schedules when using roof sheet making machines, resulting in equipment downtime, repairs, and failure.

We got you covered in today's article. The guide below has clear instructions, a detailed manual, and tips on the maintenance and safety of roofing sheet machines.

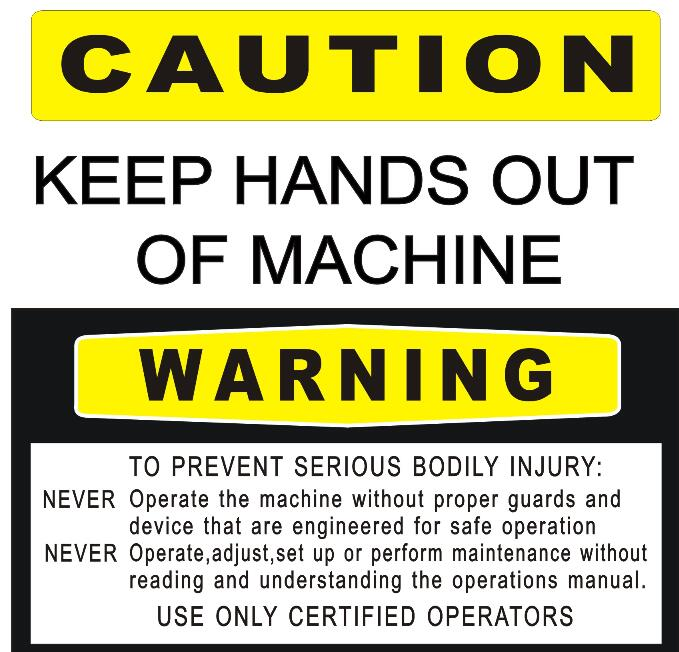

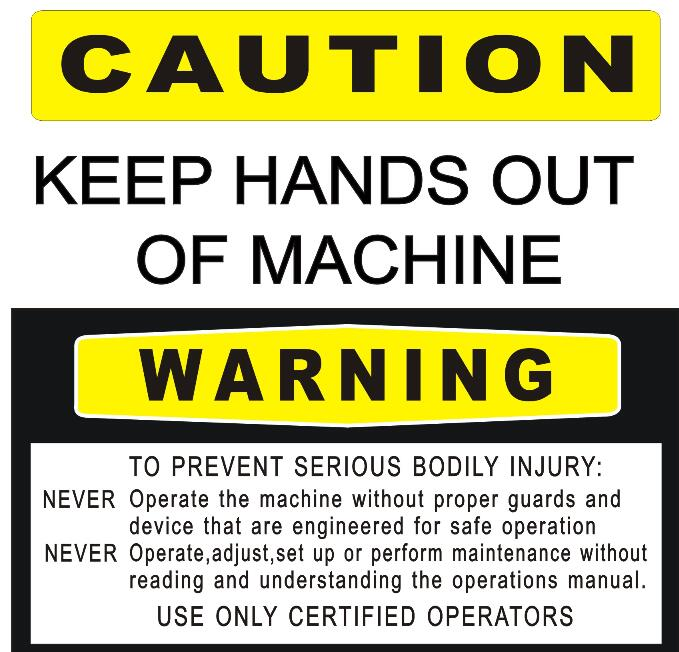

Before you do any maintenance on the roof panel machine, consider the below tips.

Carefully read and understand the roof machine manual

Always keep the guards, lids, and covers mounted to your machine during operation

Observe and follow all safety warning signs that come with the machine's manual

Adhere to the rules and follow national and local safety codes regarding unloading or loading of reeled coils

Use recommended rated devices when lifting the coils out or into forming stand assembly

Avoid wearing jewellery or loose clothing, which might entangle the moving parts of the roof roll forming machine when in operation

When performing any maintenance, adjustments, or changeover processes, stop the machine & disconnect it from the power button

Ensure you follow all the safe handling guidelines of lubricants based on SDS

Do not use the solvents when cleaning the drive rollers

Other tips for roof roll forming machine maintenance

I. Request qualified people

It is strictly forbidden for non-designated person to operate the equipment, and usually people must stop the machine when leave.

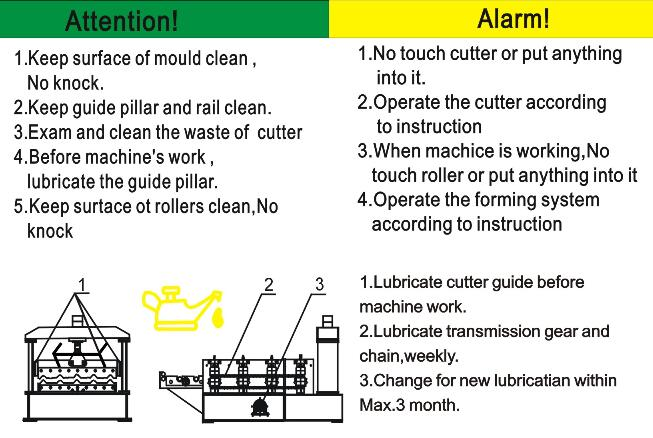

II. Main maintenance work

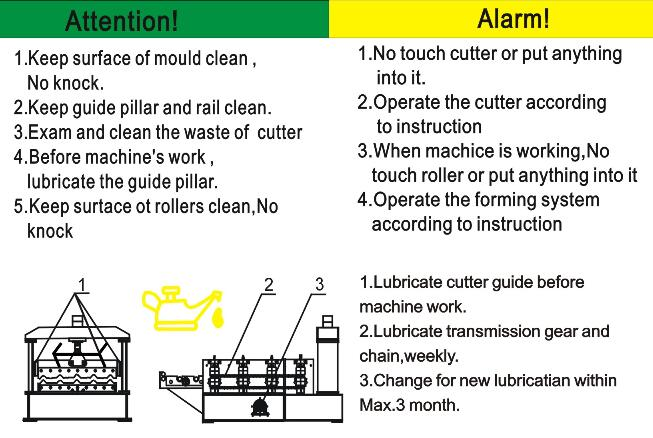

The maintenance work of the metal roll forming machine mainly includes five items: cleaning, tightening, adjustment, lubrication, and anti-corrosion.

In order to reduce the wear of mechanical parts and prolong the service life of the machinery, operators need to do the following work:

1. Routine maintenance

Routine maintenance mainly focuses on cleaning, tightening, adjustment and lubrication. Before the machine runs, during operation and after it stops running, operators must carry out various routine maintenance work in strict accordance with the requirements.

2. Regular maintenance

According to the maintenance requirements of mechanical equipment, after reaching the specified working hours, corresponding maintenance must be carried out, including the following three items:

First-level maintenance, the first-level maintenance is carried out on the basis of routine maintenance. The main work is to lubricate, tighten and check that the relevant parts have been cleaned and the three-filter work (air filter, oil filter, fuel filter).

Secondary maintenance, the main work of secondary maintenance is inspection and adjustment. Specifically, check the working conditions the lubrication system and make corresponding adjustments to eliminate the found faults. Ensure that the metal forming machine has good working performance. This content is generally completed by the mechanical operator to assist the warranty person.

The three-level maintenance is mainly placed on detection and adjustment to eliminate hidden troubles. Diagnose and check the parts that affect the performance, and then complete the necessary replacement, adjustment and troubleshooting.

III. Mainly check following items

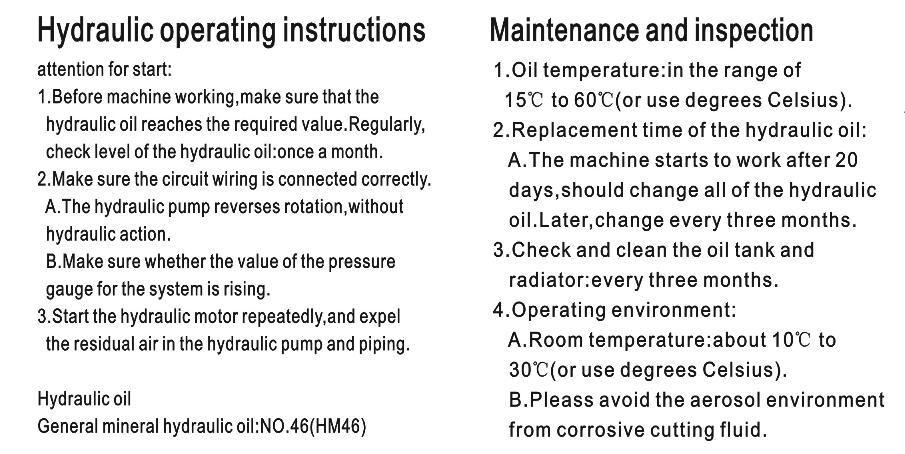

Wire circuit: Pay attention to the cleaning of the electrical circuit board, regularly clean the dust of the strong and weak electric box, keep the electric box dry and prevent moisture.

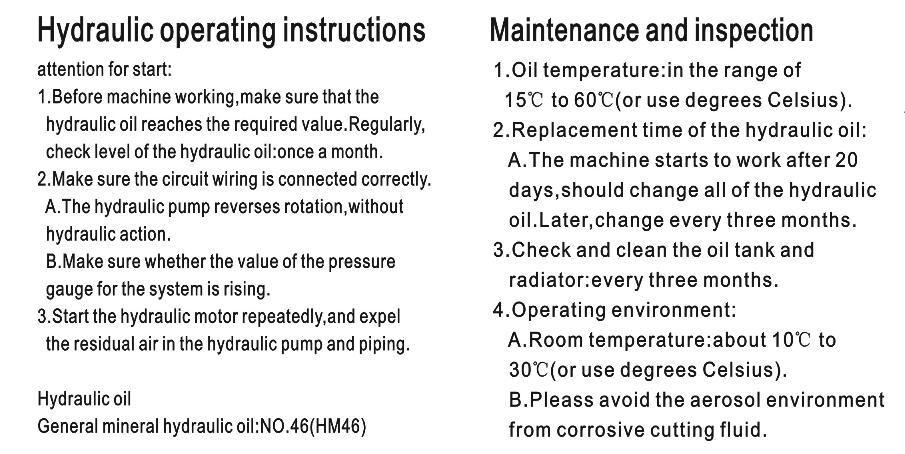

Oil circuit: Check all parts of the oil circuit for oil leakage and deal with it in time. Prevents piston rod scratches and oil deterioration.

Machinery: Check the transmission parts of the machine for wear and tear, check whether each grease nipple is blocked, and add grease (If have).

Other precautions: It is recommended to replace the hydraulic oil once three month and clean the oil tank of the oil tank. The water cooler should be cleaned in time to prevent the oil temperature from rising and the oil quality will be accelerated. Of course, safety is no trivial matter. Circuit safety door switch, oil circuit pressure relief valve, mechanical safety stopper , The machine warning light must be checked for normal operation during maintenance.

Iv. Maintenance of cutting blade

V. Maintenance of hydraulic station

Other notes:

1. This equipment has memory function. In the production process, if incur a sudden power outage , when the power has restored, start the main frame and the pump, then pressing "main frame forward" button, the machine will continue to produce, there is no need to reset the number of length and blocks.

2. If meet a state of emergency or accident, pressing "emergency stop" button to stop all operations. (Clockwise rotation "emergency stop" button for resetting)

3. All electrical components should be kept clean , cleaning once a month. In addition to the need for cleaning and adjusting, the electrical box door should be closed and not free to open.

4. If there are some faults happened during working, the machine should be repaired by the professional electrician or electrical maintenance.